Large diameter antifriction bearings for wind turbines

For more than 30 years, IMO has been producing and marketing blade, yaw, and generator bearings for onshore and offshore wind turbines around the world. IMO delivered its first tower house for wind turbines in 1988, and series production of pitch bearings for the wind energy sector began in 1996. IMO is a valued development partner for lots of renowned OEMs. IMO torque bearings are used throughout the world with an installed power of around 45 GW. In total, IMO has already supplied more than 90,000 slewing rings for the wind energy sector.

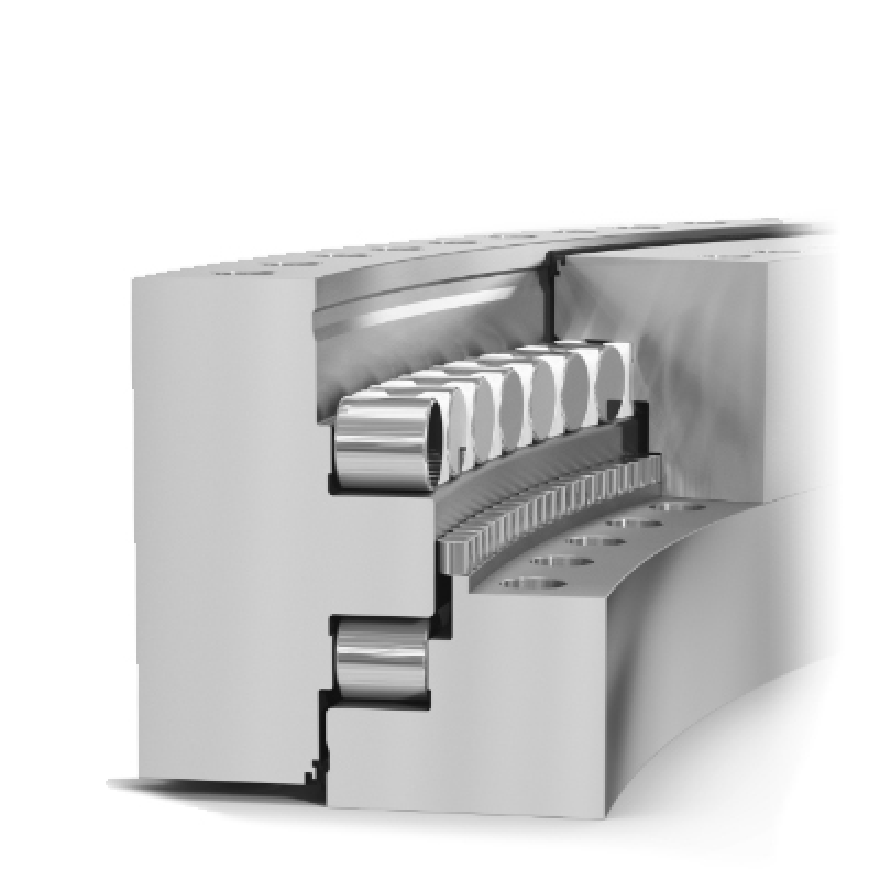

Triple-row cylinder roller bearings used as main bearings

IMO main bearings for shaftless and gearless wind turbines with direct drive are based on triple-row roller bearings that ensure top efficiency, rigidity, and resilience. Robust metal cages, special lubricants, and high-performance seals guarantee low wear and a long lifetime. Rotor bearings of this kind are available in versions with oil and grease lubrication.

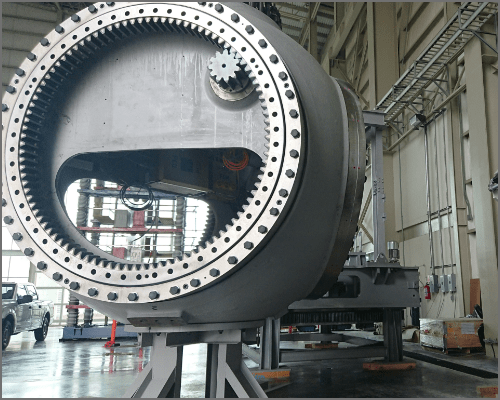

Single-row or double-row ball slewing rings as rotor blade bearings and yaw bearings

IMO yaw bearings and blade flange bearings are single-row or double-row ball bearings with hardened internal or external gearing (electrical blade adjustment) or without gearing (hydraulic pitch system). High-grade 42CrMo4QT heat-treatable steel is used as the material for the four-point bearings and double four-point bearings. IMO Service also supplies four-point/eight-point replacement bearings and replacement parts (seals etc.) for repairs in the after-sales sector.

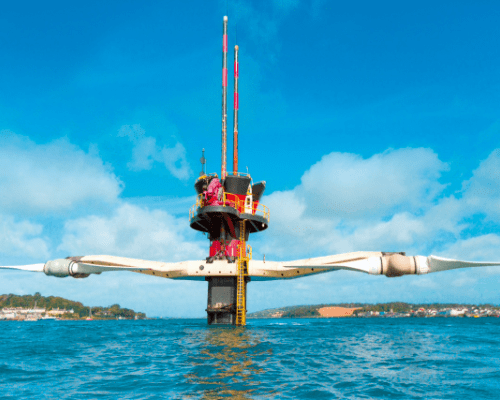

The blade bearing family of the next Generation: T-Solid and T-Solid 4IPC

IMO developed the new roller blade bearing T-Solid 4IPC for low wind site turbines and large offshore turbines with and without individual pitch control (IPC). It offers cost savings due to a higher static load carrying capacity and longer lifetimes in the pitch sector.

T-Solid is used as a pitch bearing for large rotors (onshore/offshore) with collective pitch control. It is frequently the replacement solution of choice for the premature failure of four-point blade bearings in the field.